|

| EDUCATION | CATALOG | RIGGING | CONSULTATION | HOME | CONTACT US |

|

#1

|

|||

|

|||

|

I found a web site giving the order of reeving two 3part blocks together. The illustration shows the blocks turned 90 degrees to each other with the first hauling line beginning in the center of the top block.

Yet on a local schooner they have the blocks axis's parallel and the old salt who reeved them insists he did it correctly dispite the first hauling line beginning at the end of the top sheave. Is there more than one 'correct' way to reeve these blocks?. http://constructionmanuals.tpub.com/.../14043_122.htm Last edited by Stan R : 09-26-2014 at 11:58 AM. Reason: to include a site with illustrationo |

|

#2

|

|||

|

|||

|

"Different ships, different long splices."

Those who, like myself, advocate having the axes of the blocks normal to each other like the resulting lack of kink and rubbing as you tighten up to two-blocked. Those who like the axes parallel don't care about that. G'luck |

|

#3

|

|||

|

|||

|

Hello,

While I agree with Ian that practices vary among vessels, sometimes the variance is harder to justify than others; sometimes personal or institutional preference should take a back seat to specific needs. In the case of reeving, it doesn't matter much when the blocks are far apart, but as they draw closer together any off-angles will increase, generating more and more friction and chafe, which peak just at the top of the hoist, when the loads are highest and you want the least resistance. "Right angle" or "boat fall" reeving seems like the only sensible course here. Fair leads, Brion Toss |

|

#4

|

|||

|

|||

|

Hello,

While I agree with Ian that practices vary among vessels, sometimes the variance is harder to justify than others; sometimes personal or institutional preference should take a back seat to specific needs. In the case of reeving, it doesn't matter much when the blocks are far apart, but as they draw closer together any off-angles will increase, generating more and more friction and chafe, which peak just at the top of the hoist, when the loads are highest and you want the least resistance. "Right angle" or "boat fall" reeving seems like the only sensible course here. Fair leads, Brion Toss |

|

#5

|

|||

|

|||

|

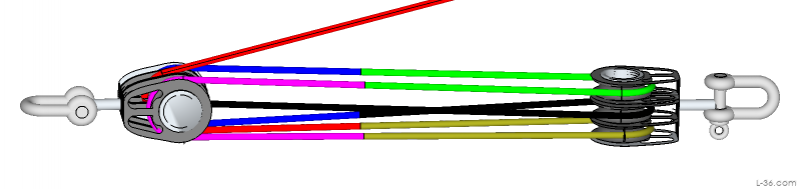

I happened to write an article on this topic not long ago. Here is an illustration from that article showing dual triple blocks:

The cross reeving almost always works out better, imho. Also, having the tail come out the center sheave of the block keeps the load even when that line is not pulled straight toward the second block as shown in this sketch. This prevents sideways twist which can cause additional friction. You will get some rotation if you do that, but it will not tilt the blocks sideways and the sheaves will stay lined up. The article is here: http://l-36.com/blocks_mechanical_advantage.php |

|

| Thread Tools | |

| Display Modes | |

|

|