|

| EDUCATION | CATALOG | RIGGING | CONSULTATION | HOME | CONTACT US |

|

#1

|

|||

|

|||

|

This version double soft shackle is stronger, easier to make, and easier to use than previous versions. It also does not constrict the sheets. What is not to like?

The idea of the double soft shackle is that you can fasten it to the sheets ahead of time and then very quickly attach it to the clew ring. I have used them for sheets and for tack lines when I wanted a way to connect a line fast under race conditions. You can see in the second photo below that the large loop can be quickly put over the stopper knot where the slightest sheet load will close the loop securing the shackle.    The center knots are basically a double bowline and a tripple fisherman's knot. The stoppers are diamond knots. I tried many variations of the center knots, each variation being stronger than the previous. My estimated breaking force for my 7/64 test version was 1,900 pounds based on the stretch of the 7/16 XLS line that went around the winch with a weight pulling on the winch handle. Sorry I am not more calibrated that that. The line is rated at 1,600 pounds but I had a test section of line in the setup and it did not break so the shackle is not as strong as the line it is made of. I wrote up my work including instructions on how to make it on my web site http://L-36.com/soft_shackle_8.php Allen |

|

#2

|

|||

|

|||

|

Quote:

composed of opposing overhand hitches abutting and locking; and so the nomenclature adds to this "double", "triple" where the components are, resp., double o.s, triple o.s --and in this scheme of things, you show but ONE component, which is a quadruple overhand ; in fact, you've tied a strangle knot (hitch) --and a triple strangle as the single contains one overwrap, unlike the overhand. (Spare any WWWeb justification, this is older than that.) Now, substantially vs. pedantically: The complexity of making, and the breaking in the center knots. Occam's Razor suggests that, since the right side of the presented structure didn't break (i.e., the eye+diamond knot stopper), there need be no further knotting to this! Simply pre-tie the line in this manner, to then loosen, reeve the eye-end through the ring, and re-attach around the stopper's throat. This makes a uniform four-strand connecting structure, not 2-vs-4 as shown (where the break came in the knotted "2" side). Beyond this admittedly *loose* simple structure of a ring of doubled HMPE connected with eye+stopper, I can think of various other ways of much the same sort of thing, with the same or similar finish, but with some added engagement to reduce the *looseness*. E.g., putting a larkshead/girth hitch around the sheets with the stopper knot centered in this, and then reeving through the ring to bring the eye (perhaps merely the bight end) through the sheets and then around the stopper. --dl* ==== |

|

#3

|

|||

|

|||

|

Dan,

I am not completely following what you are saying but let me respond to what I think you are getting at. Clearly this is not a fisherman's knot but half of one with another knot. I think you may be pointing out that the combination has a name but I am not completely sure what you are saying. It was not my intention to invent a knot but rather to have something strong and tested. As far as pre-tying and using a larkshead to attach the sheets, that was what my previous designs were. You can look up my older posts. Those designs had three shortcomings that this design solves. First is that they constrict the sheets which is a strength concern for the sheets. Second is that it is more difficult to attach than this design, although that is minor. But it turns out that this design is stronger by about 50%. With the larkshead the failure is at the larkshead and at a force about 2/3 the force that this design yields. With a smaller stopper loop, the failure would be at that end but with a larger size stopper, the failure moves to the larkshead. Finally, of the three designs I have come up with, two use the larkshead to attach the sheets, and this one is the easiest to make, has the least shortcomings, and is strong. If you go to the article I posted on my web site, you can see the other three designs that I have posted. Allen |

|

#4

|

|||

|

|||

|

Thank you Don, I have corrected my writeup to reflect that the knot is a tripple strangle hitch.

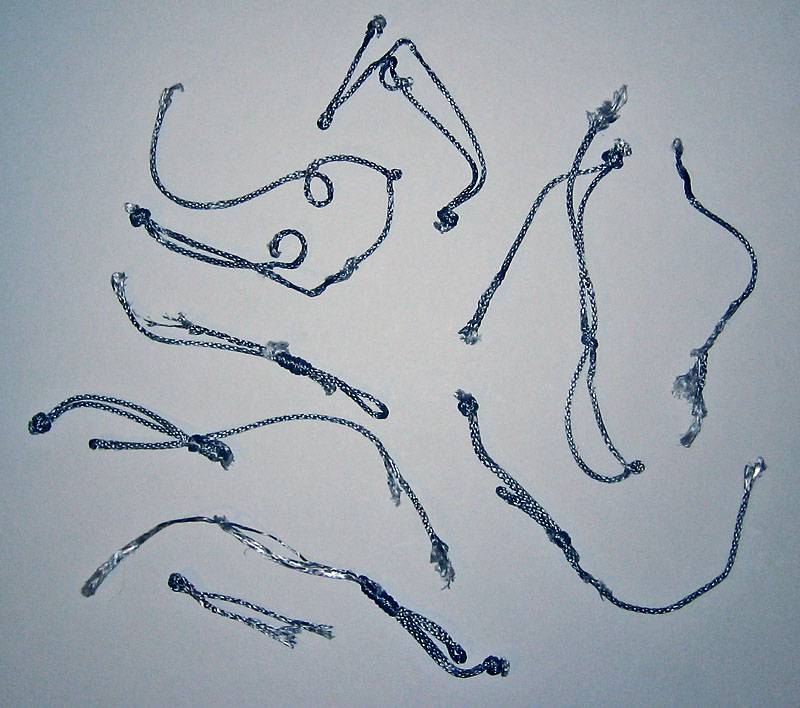

For your reference, here are the other double soft shackles designs I have posted both of which had problems solved by the design in this thread.  The problem with the above shackle is that it falls off the sheets if you don't hold it on. It also constricts the sheets although not as much as the design below.  Note that the one above with the fisherman's knot in the center would break the stopper knot that attaches to the ring. If a larger stopper knot is used to increase the strength, it breaks the shackle eye at the stopper knot. If an even larger stopper knot is used to increase the radius in the eye, then it breaks at the larkshead hitch. The largest issue I have with this design is the constriction of the sheet line. And again, the easiest to make is the one in this thread because it is so well behaved when being tightened to lock the knots. Allen Last edited by allene : 09-30-2011 at 05:50 PM. Reason: added last sentence. |

|

#5

|

|||

|

|||

|

Quote:

A nice aspect of using "strangle" (which is a double overhand ) is that the modfiers "double", "triple", ... will match the visible "overwraps" that give it such security. (Whereas, as I remarked, a "dbl.fish" has 1 overwrap, the triple, 2, and so on --mismatching.) (So, for rockclimbers, who often use dbl./trpl., going with "Grapevine (bend)" which begins with strangle (single) components, one gets the nominal matching.) Quote:

Which puts the nature of the connector the same as you have above --a twin line w/stopper being connected to the eye. At the clew end (well, this joint would be able to shift position, hitching to nothing), the twin line simply loops through it, knotless. You have 2 twin-strands spanning the connection, with a turn around the clew and the sheets --no more/less compression than above (identical), and more material throughout than any of your designes (double the doubled strands). Quote:

Now, I referred to my suggested structure as "loose", by which I mean that it isn't *hitched* in place; its only security is in the well-fit small eye choking the stoppered end, and I think that that's adequate (for loose jostling around ; certainly for full tension). If this is a concern, one can I think arrange for some more knotted structure to include a hitching of your connector to the sheets (this seems to be desired by you), and then one will again reeve the eye-end through the clew and bring it back to the sheets-end for ensnaring the stopper (which, e.g., could be positioned as the crossing arc of the larkshead --just to show an idea), perhaps preferably after doing some knotting or just turning through the sheets (thereby offloading some force before choking the stopper). Working in such slick material as HMPE, though, takes some care in choosing a hitch (perhaps a *doubled* larkshead --i.e., where the "arcing" part is a full round turn, to try to give some frictional security-- ; sometimes called "bull hitch" (stronger than "cow")). But, then, your systems --all-- seem to involve a pre-tied larkshead + stopper second piece of line on the clew, which I'd think is vulnerable to loosening and falling off! !? As for constricting the sheets, I should think that their mere turning around the thinner twin strands of the HMPE connector would be as much damaging --maybe only showing on one spot vs more generally, but ... "weakest link", still. .:. minor difference, overall. Cheers, --dl* ==== |

|

#6

|

|||

|

|||

|

AND ... , to present a further idea, though one that seems

to miss some of your design goals (in having connector at clew only, and bringing the sheets to that, vs. having the connector piece attached to the sheets initially, and all being brought to the clew), ... consider you on-the-clew larkshead + stopper. Make that longer, of adequate size (strength & length) so that the attachment process is as follows: 1) reeve stopper end through the eyes of the sheets; 2) bring stopper back to the clew end; 3) loosen the larkshead (around clew); 4) reeve stopper end through clew (CAN this be done, always?!); 5) and now tuck the stopper out between the *center* of the larkshead (i.e., between legs & between arcing part & clew), 6) and then cinch tight the larkshead to lock all. Were the clew too small to receive the stopper, the stopper could be just tucked out through the hitch directly --but then the hitch is taking full load vs. half, though I think it might be a little stronger so oriented. (NB: there is no brummel'd eye in this.) --dl* ==== |

|

#7

|

|||

|

|||

|

I am thinking you are suggesting something similar one of the variations I have on my web site but with the sheets where I show the pad-eye:

Let me clarify the application of the double soft shackle. The idea is that you have a jib out on a pole and a single sheet on the clew. You want to take the pole off, add a second sheet, and gybe. You are trying to attach a sheet to a sail that is already flying. You want to basically lasso the stopper knot that is attached (and stitched so it won't come off) to the clew. This needs to be a single hand exercise. Another application is attaching a foot line to the tack. Again, you want something very fast. Because the shackle and eye are not bent, they do not have to be adjusted or milked around any curves. These double soft shackles are very fast to attach. Faster than a standard stainless shackle. You cannot say that about anything you have to thread through the clew and put over the stopper knot. Allen |

|

#8

|

|||

|

|||

|

Allen, yes, BINGO! --that's it, with the added nicety of the

eye holding it to the ring. Would it be possible for this to be as shown (attached to clew), and then it's a an action of passing the eye-end through the sheets and then lassoing the clew-side stopper? Your emphasis for speed is what I'm missing: Quote:

- pre-tied piece w/stopper on clew; - then the connecting piece, which needs to sometime be reeved through the sheets & lassoing that side's stopper, - and finally connected by the opposite end's eye lassoing the clew piece's stopper. And this OP structure was double-strength through the sheets, but going single-strength to connect to the clew piece; so, I'm looking for a way to have it double throughout. I'm *knottically*, not nautically inclined, so pardon my ineptness to understand well your context, but I'm thinking simply that if you can reeve the right-side eye through those two red sheets and then connect eye-to-stopper there, can THIS act be the entire one? --and using an arrangement as you've just presented (which might be set on the clew vice the grey rope), the reeving and lassoing are done through the sheets and no further connection is wanting? --and you have doubled material throughout, to boot. Granted, that isn't as simple-quick as ONLY lassoing the already connected-to-two-red-sheets piece by lassoing the grey stopper; but you've done this "already connected..." step sometime. The only (dubious) thing I can think of to match your quickness is having two eyes, the tails of each leading to be joined in the stopper knot, and the bight between the eyed having itself and eye, to lasso the stopper through the sheets; this leave then the double-eyes (reeved through each other ?!) to lasso, in one fell soup, the clew's stopper knot. The "dubious" assessment comes from the need here to be so precisely measured for balance to the now two small eyes connecting pieces --their interreeving being a move to try to achieve this balance (and make the structure without an *order* to their attachment --as they jointly attach (vs. one closer, other farther, from the choked clew stopper). And "dubious" is the assurance of such intertwined small eyes gripping and not being pulled around the stopper knot (as each will have one strand of the other inside its eye). ("too clever by half" comes to mind ...  ) )--dl* ==== |

|

#9

|

|||

|

|||

|

Just for reference and to make sure I was not saying something incorrect, I did an experiment. I put the stopper loop on a coat hanger that is hanging from a rope in my garage and attached the double soft shackle to a line. With the hanger swinging back and fourth, I can easily and quickly attach the shackle and sheet to the stopper eye with one hand. You basically hold the open eyed shackle in your hand and grab the stopper knot pushing the eye onto the stopper. Then you let go of the shackle, keeping hold of the stopper knot. Gravity tightens the shackle and it is attached. It is very fast.

I have used normal soft shackles a lot over the last year. They are not easy to put on. The idea of my line shackle and this double soft shackle is that with the working part of the shackle straight, it closes very easily. When you double it back, it is not so easy. In terms of strength, this double soft shackle is not as strong as the line it is made of from but it is very close. In my test, I put about 1900 pounds on a 7/64 line. The line is rated at 1600 pounds so while I put more than the rating of the line, I did not break a test section of line so it is not as strong as the line but close. For the real shackles, I am using 5/32 line which is rated at 4000 pounds. If I was using 7/16 XLS line, typical line for my boat, with a bowline on it reducing the strength by 40% I would have about 3500 pound strength. So, without even going to 3/16 line, I get an attachment that is as strong as I would have using a bowline. The point is, I don't need the double strength. I do appreciate your correction on the name of the knot. I used the knots I did because I analyzed what broke and modified what I had to make them stronger. There were many iterations and I wasn't completely sure what to call what I ended up with. The double bowline is not a double bowline as it has that line coming back through the "rabbit hole". That adds greatly to the strength but it is not a bowline. I just call it that because it is otherwise a bowline. By the way, there are many iterations of soft shackles including a new standard soft shackle on my web site. You might enjoy looking it over if you have not done so already. http://L-36.com Allen  |

|

#10

|

|||

|

|||

|

Hi,

The good folks at New England Rope have sent me a length of their 12-strand Spectra, 5/16", to give to you for some destruction-testable shackle fabrication. Contact me at rigging@briontoss.com with an address to send the piece to, okay? Fair leads, Brion Toss |

|

| Thread Tools | |

| Display Modes | |

|

|